Progressive cavity pumps have gained significant attention in various industries due to their unique design and operational efficiency. These pumps are particularly valuable in applications that require the handling of viscous fluids, making them an ideal choice for the food and beverage sector. In this article, we will explore the benefits of progressive cavity pumps, including the specialized food grade progressive cavity pumps.

What are Progressive Cavity Pumps?

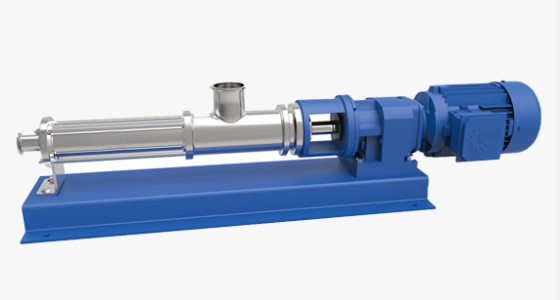

Progressive cavity pumps consist of a helical rotor and a stator, which work together to create a cavity that moves fluids from the inlet to the outlet. This design allows for a smooth and continuous flow, making them suitable for a wide range of applications.

Key Benefits

Gentle Handling of Fluids

One of the standout features of progressive cavity pumps is their ability to handle delicate fluids without causing damage. This is especially important in the food industry, where maintaining the integrity of the product is crucial. The gentle pumping action minimizes shear stress, preserving the quality of food products.

Versatility in Applications

Progressive cavity pumps are versatile and can handle a variety of fluids, including slurries, pastes, and even shear-sensitive materials. This versatility makes them suitable for various applications within the food sector, such as transferring sauces, creams, and other viscous products.

Consistent Flow Rate

These pumps provide a consistent flow rate regardless of changes in viscosity or pressure, ensuring that production processes remain stable. This reliability is essential in food processing, where precise measurements and consistent output are necessary for quality control.

Easy Maintenance

Progressive cavity pumps are designed for ease of maintenance. Their simple construction allows for quick disassembly and reassembly, reducing downtime during maintenance activities. This is particularly beneficial in fast-paced food production environments where time is of the essence.

Food Grade Options

When it comes to food applications, using food grade progressive cavity pumps is essential. These pumps are made from materials that comply with food safety standards, ensuring that they do not contaminate the products being processed. Choosing food grade options not only helps in maintaining hygiene but also enhances consumer trust in the product quality.

Conclusion

In summary, progressive cavity pumps offer numerous benefits that make them an excellent choice for various industries, particularly in food processing. Their ability to handle viscous fluids gently, provide consistent flow rates, and require minimal maintenance makes them indispensable. When selecting pumps for food applications, opting for food grade progressive cavity pumps ensures compliance with safety standards and preserves product integrity. With these advantages, it’s clear why progressive cavity pumps are becoming increasingly popular in the food and beverage sector.